Description

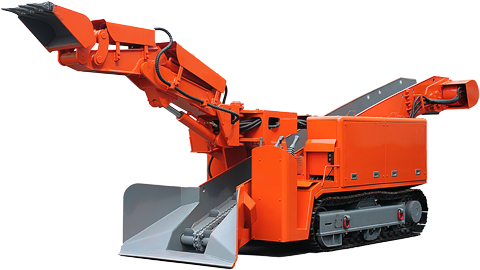

It is used for mining of coal, mixed faces the fortress of rocks less than f = 5, as well as the workings of softwood and construction of utility tunnels. Roadheader can cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has great potential in the destruction of the manual control of the breed. Roadheader has a configuration corresponding to a high international level, internal and external control systems with dust. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, easy to manage and maintain. Comprehensive electrical protection higher than the national standard.

It is used for mining of coal, mixed faces the fortress of rocks less than f = 5, as well as the workings of softwood and construction of utility tunnels. Roadheader can cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has great potential in the destruction of the manual control of the breed. Roadheader has a configuration corresponding to a high international level, internal and external control systems with dust. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, easy to manage and maintain. Comprehensive electrical protection higher than the national standard.

The hydraulic system of tunnel boring machine has the function to maintain a constant pressure in the hydraulic system, the pressure in the line contour cutting and loading circuit is sensitive overload protection. The machine is widely used for drilling in different directions for tunneling faces the soft coal and mixed faces, for penetration of softwood. Also harvester used for laying railway tracks and roads, as well as for the installation of water reservoirs.

Removable cross-sectional area from one position - 13.5 m², a longitudinal tilt angle ± 17º. The optimum height for the job - 2,1-3,2 m.

Main parameters

| Weight (t) | 21 |

| Product Parameters Locating Section Size (W×H) (m) | 3,3х4,3 |

| Dinting Depth (mm) | 180 |

| Ground Clearance (mm) | 170 |

| Track Height (mm) | 380 |

| Gradeability | ±17° |

| Economic Cutting Hardness (MPa) | ≤ 50 |

| Ground Specific Pressure (MPa) | 0,12 |

| Rotating Speed of Cutting Head (r/min) | 44 |

| Spray Type | Internal & External Spraying |

| Working Pressure of Internal Spraying (MPa) | 3,0 |

| Cutting Head Mode | Spherical, Conical Pick |

| Motor Power (kW) | 55 |

| Oil Pump Motor Power (kW) | 45 |

| Gear Rotating Speed (r/min) | 33 |

| Loading Chain Wheel Type | Four-axis |

| Conveying Capacity (m3/min) | 2,4 |

| Rated Chain Speed of Scraper (m/min) | 60 |

| Travelling Speed of Roadheader (m/min) | 3,2/6,4 |

| Braking System | Stable and Reliable |

| Driving Mode of Travelling Part | Hydraulic |

| Oil Tank Capacity (L) | 360 |

| Voltage (V) | 660 |

| Hydraulic System Pressure (MPa) | 18 |

| Hydraulic Pump | Double-piston |

| Max. Non-removable Part Dimensions (m) | 2,84х0,93х1,12 |

Description

Roadheader EBZ-100 is used for mining of coal, mixed faces the fortress of rocks less than f = 6, the workings of softwood, as well as the laying of engineering tunnels. Harvester can cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has great potential in the destruction of the manual control of the breed. miner combine is configured to match the highest international level, internal and external control systems with dust. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, easy to manage and maintain. Comprehensive electrical protection higher than the national standard. This roadheader is safe compact remote control, which is easy to manage it.

Roadheader EBZ-100 is used for mining of coal, mixed faces the fortress of rocks less than f = 6, the workings of softwood, as well as the laying of engineering tunnels. Harvester can cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has great potential in the destruction of the manual control of the breed. miner combine is configured to match the highest international level, internal and external control systems with dust. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, easy to manage and maintain. Comprehensive electrical protection higher than the national standard. This roadheader is safe compact remote control, which is easy to manage it.

miner combine is widely used for drilling in different directions for tunneling faces the soft coal and mixed faces, for sinking on soft rocks. Also, it is used for laying railway tracks and roads, as well as for the installation of water reservoirs.

Removable cross-sectional area from one position - 24 m ², a longitudinal tilt angle ± 18º. The optimum height for the job - 2.5-4.0 m.

Main parameters

| Dimensions (m) | 8.72×2.8×1.5 |

| Weight (t) | 28,8 |

| Technical Parameters Locating Cutting Section Size (W×H) (m) | 4,6х5,3 |

| Dinting Depth (mm) | 220 |

| Ground Clearance (mm) | 180 |

| Track Height (mm) | 350 |

| Gradeability | ±18° |

| Economic Cutting Hardness (MPa) | ≤ 60 |

| Ground Specific Pressure (MPa) | 0,129 |

| Rotating Speed of Cutting Head (r/min) | 44 |

| Spray Type | Internal & External Spraying |

| Working Pressure of Internal Spraying (MPa) | 3,0 |

| Cutting Head Mode | Spherical, Conical Pick |

| Motor Power (kW) | 100 |

| Oil Pump Motor Power (kW) | 55 |

| Gear Rotating Speed (r/min) | 35 |

| Loading Chain Wheel Type | Four-axis |

| Conveying Capacity ( m3/min) | 3,0 |

| Scraper Chain Speed ( m/min) | 70 |

| Travelling Speed of Roadheader (m/min) | 3,2/6,4 |

| Braking System | Stable and Reliable |

| Driving Mode of Travelling Part | Hydraulic |

| Telescopic Distance of Cutting Head (mm) | 510 |

| Oil Tank Capacity (L) | 400 |

| Voltage (V) | 1140/660 |

| Hydraulic System Pressure (MPa) | 18 |

| Hydraulic Pump | Double-piston |

| Max. Non-removable Part Dimensions (m) | 3,0х1,0х1,37 |

Description

Specially designed for construction of tunnels in the construction of the subway connecting the grid to 380

Roadheader EBZ-100A is used for mining of coal, mixed faces the fortress of rocks less than f = 6, the workings of softwood, as well as the laying of engineering tunnels. Harvester can cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has great potential in the destruction of the manual control of the breed. Roadheader has a configuration corresponding to a high international level, internal and external control systems with dust. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, easy to manage and maintain. Comprehensive electrical protection higher than the national standard. This roadheader is safe compact remote control, which is easy to manage. Roadheader is widely used for drilling in different directions for tunneling faces the soft coal and mixed faces, for penetration of softwood. Also, it is used for laying railway tracks and roads, as well as for the installation of water reservoirs.

Roadheader EBZ-100A is used for mining of coal, mixed faces the fortress of rocks less than f = 6, the workings of softwood, as well as the laying of engineering tunnels. Harvester can cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has great potential in the destruction of the manual control of the breed. Roadheader has a configuration corresponding to a high international level, internal and external control systems with dust. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, easy to manage and maintain. Comprehensive electrical protection higher than the national standard. This roadheader is safe compact remote control, which is easy to manage. Roadheader is widely used for drilling in different directions for tunneling faces the soft coal and mixed faces, for penetration of softwood. Also, it is used for laying railway tracks and roads, as well as for the installation of water reservoirs.

Removable cross-sectional area from one position - 24 m ², a longitudinal tilt angle ± 18º. The optimum height for the job - 2.5-4.0 m.

Main parameters

| Technical Parameters | |

| Length (Without Reversed Loader) (m) | 9,22 |

| Length (With Reversed Loader) (m) | 15,4 |

| Shovel Borad Width (m) | 2 |

| Outer Width of Track (m) | 1,96 |

| Width of Machine Body (m) | 1,99 |

| Max. Feeding Height (m) | 1,95 |

| Working Height of Cutting Head (m) | 1,87 |

| Weight (t) | 30 |

| Ground Clearance (mm) | 245 |

| Dinting Depth (Dinting Depth of Cutting Head) (mm) | 410 |

| Dinting Depth (Shovel Board) (mm) | 410 |

| Loading Height (mm) | 350 |

| Gradeability | ±14° |

| Economic Cutting Hardness (MPa) | ≤50 |

| Total Power (kW) | 162,5 |

| Manufacturing Parameters, Locating Section Size (m) | 5,17 (H) х 5,58 (W) |

| Locating Cutting Area (m2) | 25 |

| Gantry Height (mm) | 380 |

| Non-removable Part Dimensions (m) | 3.0 х 1.0 х 1.37 |

| Max. Non-removable Part Dimensions (m) | 3,0х1,0х1,37 |

| Max. Non-removable Part Weight (t) | 5,5 |

| Cutting Part | |

| Cutting Head Mode | Spherical, Conical Pick |

| Rotating Speed of Cutting Head (r/min) | 46 / 23 |

| Motor Power (kW) | 100 / 60 |

| Telescopic Distance of Cutting Head (mm) | 560 |

| Pick Quantity | 30 |

| Spray Type | Internal & External Spraying |

| Shovel Board Part | |

| Loading Type | Four-axis |

| Conveying Capacity (m3/min ) | 2 |

| Coal Feeder Width (Shovel Board Width) (m) | 2 |

| Dinting Depth (shovel board) (mm) | 410 |

| Lifting Height of Shovel Board (mm) | 341 |

| Reversed Loader | |

| Type | Twin Outboard Chain Scraper |

| Motor Conveying Capacity (m3/min) | 4 |

| Chute Size (mm) | 500 * 285 (w * h ) |

| Chian Speed (m/min) | 58 |

| Travelling Part | |

| Type | Caterpillar |

| Travelling Speed (m/min) | 3.5 / 7 |

| Track Width (mm) | 450 |

| Ground Specific Pressure (MPa) | 0,14 |

| (Chain Track) Chain-tension Method | Cylinder |

| Hydraulic System | |

| System Pressure (MPa) | 15,7 |

| Oil Tank Capacity (L) | 400 |

| Oil Pump Motor Power (kW) | 55 |

| Hydraulic Motor | |

|

125 |

|

IAM1200 H4 |

|

IAM400 H2 |

|

16 |

| Direction Change of Manual Lever | 5 groups |

| Cooling Method | Water |

| Cylinder Quantity (piece) | 14 |

| Spray System | |

| Dust Suppression | Internal & External Spraying |

| Consumption (L/min) | 100 |

| Nozzle Pressure of External Spraying (MPa) | 1,5 |

| Nozzle Pressure of Internal Spraying (MPa) | 3 |

| Belt Conveyor | |

| Length (m) | 7,1 |

| Weight (t) | 2,55 |

| Max. Height (m) | 2,15 |

| Min. Height (m) | 0,8 |

| Transverse Swing Ability (m) | 5 |

| Swing Angle (°) | 15 |

| Belt Speed (m/min) | 1,6 |

| Belt Width (mm) | 650 |

| Parameters of Electric Drum | |

|

7,5 |

|

76 |

|

380 |

|

400 |

| Electrical Equipment | |

| 1. Main Circuit | |

| Rated Voltage (V) | AC380 |

| Rated Current (A) | ≤315 |

| Rated Frequency (Hz) | 50 |

| Output | 4 |

| Rated Power (kW) | 162,5 |

| 2. Control Unit | |

| Type | CXH4-24E |

| Degree of Protection | Explosion-proof |

| Rated Voltage (V) | DC24 |

| Rated Power (kW) | <4.8 |

| 3. Power Switch | |

| Size and Type | KXJ1-163 / 380E-4 |

| Degree of Protection | Explosion-proof |

| Rated Voltage (V) | |

|

AC380 |

|

AC36V, AC220V, AC24V, DC24V, DC12V,AC120V, AC100V |

| Rated Current (A) | ≤315 |

| 4. Motor Working Principle | |

| Type | Asynchronous, Explosion-proof, Water Cooling |

| Model | DEBD-100 / 60-4 / 8S, H Insulation, Type of Work S2 |

| Rated Voltage (V) | AC380 |

| Rated Current (A) | 190 / 165 |

| 5. Oil Pump Motor | |

| Type | Asynchronous, Explosion-proof, Water Cooling |

| Model | YBU-55 (Univoltage),Insulation Grade H, Type of Work S1 |

| Rated Voltage (V) | AC380 |

| Rated Current (A) | 105 |

| 6. Braking System | |

| Type | |

| Size and Model | Explosion-proof |

| Rated Voltage (V) | BZA2-5 / 36J (A) Interlock Device |

| Rated Current (A) | AC36V |

| Application | 5 |

|

|

|

|

| 7. Electric Bell | |

| Type | Explosion-proof |

| Size and Model | BAL1-127 |

| Rated Voltage (V) | AC127 |

| Rated Current (A) | 0,35 |

| 8. Lighting | |

| Type | Explosion-proof |

| Size and Model | DGE15 / 24L (A) |

| Rated Voltage (V) | AC24 |

| Rated Power (W) | 15 |

| Quantity (piece) | 3 |

| 9. Methane Sensor (Gas Sensor) | |

| Type | CJG4, Explosion-proof |

| Rated Voltage (V) | DC18 |

| Rated Current (mA) | 320 |

Description

Roadheader EBZ-132 used for mining of coal mixed with the hardness of rock faces no more than 70 MPa, the workings of softwood and for wiring engineering tunnels. It can be cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has a large manual control and destruction of species. miner combine is configured to match the highest international level, inner and outer dust protection system. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, which can be used in managing and servicing. Comprehensive electrical protection higher than the national standard.

Roadheader EBZ-132 used for mining of coal mixed with the hardness of rock faces no more than 70 MPa, the workings of softwood and for wiring engineering tunnels. It can be cut, load and transport the rock mass simultaneously with loading railcars, conveyor belts and motorized belts. Harvester has a compact design, low center of gravity, easy to manage, has a large manual control and destruction of species. miner combine is configured to match the highest international level, inner and outer dust protection system. Gearbox and hydraulic suspension combine integrated and highly integrated. The middle part of the transport system has a joint and a large dump height. The combine has an LCD display with a demonstration of the functions in the dynamics, which can be used in managing and servicing. Comprehensive electrical protection higher than the national standard.

The hydraulic system miner combine has a function to maintain a constant pressure in the hydraulic system, the pressure in the line contour cutting and loading circuit is sensitive overload protection. This processor is a portable secure remote control and the combined group of valves. The processor used in several new patent technology.

miner combine EBZ-132 is widely used for drilling in different directions for tunneling faces the soft coal and mixed faces, for penetration of softwood. Also, it is used for laying railway tracks and roads, as well as for the installation of water reservoirs.

Removable cross-sectional area from one position - 20,1 m 2, a longitudinal tilt angle ± 18 0. The optimum height for the job - 2,2-3.3 m.

miner combine EBZ-132 is a crawler designed for the average mode, having the executive body of the election type. Harvester is used for sinking mines and tunnels. Combine a electrohydraulic drive system and a modular design for easy transportation, installation / removal and maintenance. Mountain mass bounces rotating cutting body is located on the harvester boom. Cutting body driven by a motor with water cooling via a two-speed epicyclic gearboxes and.

The manipulation of the boom is done vertically, horizontally and in an arc using the hydraulic cylinders and moves freely in the work, allowing selectively run in the bottom of any production profile. Dust suppression system is located on the boom and a set of nozzles irrigate the treated area under irrigation and clove through the nozzles on the executive board.

If you want to roadheader can be equipped with a high-pressure irrigation system. Standard executive body of the axial type motor has a capacity of 132 kW. Repulsed rock mass is going on the feeder as it moves to the bottom of the combine. The feeder can be raised and lowered as necessary to ensure proper clearance at the stretch of the combine or work rebellion / fall produce. The feeder is equipped with a shovel stars that move the rock mass to the scraper conveyor, mounted in the center of the combine. Stars are hydraulically driven via gears mounted under the feeder.

The scraper conveyor drive is equipped with two hydraulic motors on the collapse of the conveyor and docked with the feeder is mounted on the front and rear hinge arms combine. This arrangement allows the conveyor to move with the feeder when lowering / lifting of the latter. The scraper conveyor transports the material is chipped into the tail of the car, where the shipment takes place in the mine transport systems. Motion miner combine by using trucks. Truckee driven by a hydraulic motor through a gearbox. Each motor has a built-in trucking braking system, which is triggered when disconnecting the electrical or hydraulic systems. The brake system is also activated if the control lever Tracians in neutral. Truckee have a low ground pressure, allowing you to work in a very soft soil.

Behind the combine are auxiliary jacks for lifting it. These jacks are used to stabilize the harvester at work as well as the passage of the inclined workings. In addition, jacks may be used in servicing processor. The hydraulic system is equipped with oil station, consisting of a piston pump, resulting in the operation of the motor with air cooling. The hydraulic system consists of a number of high-pressure circuits and control circuits and control. All hose connections and fittings are equipped with the BRC, which makes all the hydraulic circuits are easy to service.

Cooling hydraulic and engine cutting unit is carried out using a water system miner combine . Water system directs the flow of coolant through the cooling oil tank and through the engine water jacket cutter body. Once the water has passed through all the single phase cooling system, it may be applied to the dust suppression system or removed through the drain line. Water system of the machine is equipped with pressure sensors and flow of water. The sensors are connected to an electrical control circuit, which allows the engine to run the executive body only if the required level of flow / pressure water, providing cooling and irrigation.

Technical specification

Roadheader EBZ-132 for the average mode is generally described in technical specifications and skomplektovat of:

EXECUTIVE BODY:

- Electoral executive body with a single cutting tool and irrigation under the tooth.

Loading systems and conveyors:

- Hydraulic shovel asterisk.

- The hydraulically adjustable feeder.

- Conveyor with hydraulic drive, double-row round-link chain.

TRACKS

- The hydraulic drive system of trucking.

- The safety brake.

- Automatic hydraulic track chain tension.

Hydraulic equipment:

- Oil station.

- БРС.

- Automatic and manual pumping oil in the oil tank.

COOLING SYSTEM:

- Open cooling method.

ELECTRIC EQUIPMENT:

- The electrical contactor control station.

- Engine oil station.

- Engine cutting body.

- Two headlights.

- Two taillights.

- Prestart alert.

- The emergency stop button machines.

- Pressure sensors & water discharge.

JACKS:

- 2 fixed jack.

EQUIPMENT FOR LUBRICANTS:

- Individual lubricant through a grease fittings.

| Machine Parameters | |

| Machine Length | 8950 mm |

| Machine Height | 1480 mm |

| Machine Width | 2800 mm |

| Total Weight (Standard Configuration) | 45 t |

| Ground Clearance | 210 mm |

| Max. Non-removable Part Dimensions | 3,4 х1,39х1,28 m |

| Cutting Parameters | |

| Max. Cutting Height | 4000 mm |

| Max. Cutting Width | 5100 mm |

| Min. Working Height | 1700 mm |

| Dinting Depth | 200 mm |

| Cutting Motor Power | 132 кW |

| Rotating Speed of Cutting Head | 44 r/min |

| Economic Cutting Hardness | ≤ 70 МPа |

| Scraper Conveyor | |

| Conveyor Type | Double Circuit, Fixed |

| Link Specifications | 18х64 |

| Rated Chain Speed of Scraper | 61 m/min |

| Conveyor Driver | Hydraulic |

| Loading and Conveying System | |

| Loading Mode | Chain Wheel |

| Driving Mode of the Star Wheel of Shovel Board | Hydraulic |

| Loading Chain Wheel Type | Four-axis |

| Gear Rotating Speed | 33 r/min |

| Conveying Capacity | 3,4 m3/min |

| TRACKS | |

| Travelling Speed | 0 - 6,0 m/min |

| Motor Mode | Hydraulic |

| Track Height | 700 mm |

| Ground Specific Pressure | 0,135МPа |

| Gradeability | ±18° |

| Oil Station | |

| Motor of Oil Station | 75 кW |

| System Pressure | 18 МPа |

| Oil Tank Capacity | 500 l |

| Water Consumption | |

| Dust Suppression | Internal & External Spraying |

| Spray Water Pressure | 3 МPа |

| Electrical Equipment | |

| Supply Voltage | 140/660В 50 Hz |

| Oil Pump Motor Power | 75 кW |

| Cutting Motor Power | 132 кW |

| Total Power | 207 кW |

Description

Roadheader EBZ-160 used for mining of coal, mixed faces, as well as used for tunneling. When tunneling and rock cutting coal combine rock fortress used to no more than 75 MPa. These conditions are best for cutting, loading and transporting rocks. The layout of miner combine a compact, low center of gravity, easy to manage perfectly works on the uprising, destroying confidence strong breed. The cutting of the miner combine has a telescopic body, external and internal irrigation, used for dust suppression. Reducer working body and the motor are combined and highly integrated. Maternal body assembly line is located in the center, is a straight line and a large dump height. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage and maintain. Standard electrical equipment higher than the national standards. The hydraulic system has a function to maintain a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection. Compact size and easy control unit creates a significant safety at work. The processor used in several new patent technology.

Roadheader EBZ-160 used for mining of coal, mixed faces, as well as used for tunneling. When tunneling and rock cutting coal combine rock fortress used to no more than 75 MPa. These conditions are best for cutting, loading and transporting rocks. The layout of miner combine a compact, low center of gravity, easy to manage perfectly works on the uprising, destroying confidence strong breed. The cutting of the miner combine has a telescopic body, external and internal irrigation, used for dust suppression. Reducer working body and the motor are combined and highly integrated. Maternal body assembly line is located in the center, is a straight line and a large dump height. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage and maintain. Standard electrical equipment higher than the national standards. The hydraulic system has a function to maintain a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection. Compact size and easy control unit creates a significant safety at work. The processor used in several new patent technology.

miner combine is widely used both in deep mines at large angles of incidence of soft coal seams, in the sinking of mixed faces and in tunneling for railways, highways and reservoirs. Most Removable cross-sectional area from one position - 25.4 m², a longitudinal tilt angle ± 18º. The optimum height for the job - 2,5-4.0 m. miner combine EBZ-160 is a crawler designed for the average mode, having the executive body of the election type. Harvester is used for sinking mines and tunnels. Combine a electrohydraulic drive system and a modular design for easy transport, assembly / disassembly and maintenance.

Mountain mass bounces rotating cutting body is located on the harvester boom. Cutting body driven by a motor with water cooling via a two-speed epicyclic gearboxes and. Manipulation of the boom is done vertically / horizontally and with the help of hydraulic cylinders arc and moves freely in allowing selectively run in the bottom of any production profile. Dust suppression system is located on the boom and a set of nozzles irrigate the treated area under irrigation and clove through the nozzles on the executive board. If necessary, combine harvester can be fitted with high-pressure irrigation system. The executive body is equipped with a telescopic device allowing to nominate the executive body of 550 mm, for the convenience of taking the pits when attaching the frame or arch support. Auxiliary mounting arch support is also located on the boom.

Standard executive body of the axial type motor has a power of 160 kW. Repulsed rock mass is going on the feeder as it moves to the bottom of the combine. The feeder can be raised and lowered as necessary to ensure proper clearance at the stretch of the combine or work rebellion / fall produce. The feeder is equipped with a shovel stars that move the rock mass to the scraper conveyor, mounted in the center of the combine. Stars are hydraulically driven via gears mounted under the feeder. The scraper conveyor drive is equipped with two hydraulic motors on the collapse of the conveyor and docked with the feeder is mounted on the front and rear hinge arms combine. This arrangement allows the conveyor to move with the feeder when lowering / lifting of the latter. The scraper conveyor transports the material is chipped into the tail of the car, where the shipment takes place in the mine transport systems.

The movement of the combine by means of trucks. Truckee driven by a hydraulic motor through a gearbox. Each motor has a built-in trucking braking system, which is triggered when disconnecting the electrical or hydraulic systems. The brake system is also activated if the control lever Tracians in neutral. Truckee have a low ground pressure, allowing you to work in a very soft soil. Behind the machine are auxiliary jacks for lifting the combine. These jacks are used to stabilize the harvester at work as well as the passage of the inclined workings. In addition, jacks may be used in servicing processor. The hydraulic system is equipped with oil station, consisting of a piston pump, resulting in the operation of the motor with air cooling. The hydraulic system consists of a number of high-pressure circuits and control circuits and control.

All hose connections and fittings are equipped with the BRC, which makes all the hydraulic circuits are easy to service. Cooling of the hydraulic system and engine cutter body carried out by means of an aqueous vehicle. Water system directs the flow of coolant through the cooling oil tank and through the engine water jacket cutter body. Once the water has passed through all the single phase cooling system, it may be applied to the dust suppression system or removed through the drain line. Water system of the machine is equipped with pressure sensors and flow of water.

Technical specification

The sensors are connected to an electrical control circuit, which allows the engine to run the executive body only if the required level of flow / pressure water, providing cooling and irrigation.

TECHNICAL SPECIFICATION

Roadheader EBZ-160 for the average mode, in general, is described in the technical specifications and of collected of the following:

EXECUTIVE BODY:

- Electoral executive body with one cutting unit and irrigation under the tooth.

Loading systems and conveyors:

- Hydraulic shovel asterisk.

- The hydraulically adjustable feeder.

- Conveyor with hydraulic drive, double-row round-link chain.

TRACKS:

- The hydraulic drive system of trucking.

- The safety brake.

- Automatic hydraulic track chain tension.

Hydraulic equipment:

- Oil station.

- БРС.

- Automatic and manual pumping oil in the oil tank.

COOLING SYSTEM:

- Open cooling method.

ELECTRIC EQUIPMENT:

- The electrical contactor control station ..

- The motor oil station.

- The motor of the cutting body.

- Two headlights.

- Two taillights.

- Prestart alert.

- The emergency stop button machines.

- Pressure sensors water discharge.

JACKS:

- 2 fixed jack.

EQUIPMENT FOR LUBRICANTS:

- Individual lubricant through a grease fittings.

| Technical Parameters | |

| Machine Length | 9440 mm |

| Machine Height | 1650 mm |

| Machine Width | 2900 mm |

| Total Weight (Standard Configuration) | 45 t |

| Ground Clearance | 260 mm |

| Max. Non-removable Part Dimensions (L×W×H) | 3,5х1,2х1,5 m |

| Cutting Parameters | |

| Max. Cutting Height | 4800 mm |

| Max. Cutting Width | 5400 mm |

| Dinting Depth | 200 mm |

| Cutting Motor Power | 160 кW |

| Rotating Speed of Cutting Head | 23 и 46 r/min |

| Telescopic Distance of Cutting Head | 550 mm |

| Economic Cutting Hardness | ≤ 75 МPа |

| Scraper Conveyor | |

| Conveyor Type | Fixed Double Circuit |

| Link Specifications | 18х64 |

| Rated Chain Speed of Scraper | 61 m/min |

| Driving Mode of Conveyor | Hydraulic |

| Loading and Conveying System | |

| Loading Mode | Chain Wheel |

| Driving Mode of the Star Wheel of Shovel Board | Hydraulic |

| Loading Chain Wheel Type | Four-axis |

| Gear Rotating Speed | 33 r/min |

| Conveying Capacity | 3,4 m³/min |

| TRACKS | |

| Travelling Speed (Rated Travelling Speed) | 0 - 6,0 m/min |

| Motor Mode | Hydraulic |

| Track Height | 450 mm |

| Ground Specific Pressure | 0,14МPа |

| Gradeability | ±18° |

| Oil Station | |

| Motor of Oil Station | 75 кW |

| System Pressure | 18 МPа |

| Oil Tank Capacity | 500 l |

| Water Consumption | |

| Dust Suppression | Internal & External Spraying |

| Working Pressure of Internal Spraying | 3 МPа |

| Electrical Equipment | |

| Supply Voltage | 1140/660В 50 Hz |

| Oil Pump Motor Power | 75 кW |

| Cutting Motor Power | 160/80 кW |

| Total Power | 235 кW |

Description

Roadheader EBZ-220 used for mining of coal, mixed faces, as well as used for tunneling. When tunneling and rock cutting coal combine fortress used to no more than 75 MPa. These conditions are best for cutting, loading and transporting rocks. Layout combine compact, low center of gravity, easy to manage, it works perfectly for an uprising, destroying confidence strong breed. The cutting portion has a telescopic body, external and internal irrigation, used for dust suppression. Reducer working body and the motor are combined and highly integrated. Maternal body assembly line is located in the center, is a straight line and a large dump height. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage iobsluzhivanii. Standard electrical equipment higher than the national standards. The hydraulic system has a function to maintain a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection.

Roadheader EBZ-220 used for mining of coal, mixed faces, as well as used for tunneling. When tunneling and rock cutting coal combine fortress used to no more than 75 MPa. These conditions are best for cutting, loading and transporting rocks. Layout combine compact, low center of gravity, easy to manage, it works perfectly for an uprising, destroying confidence strong breed. The cutting portion has a telescopic body, external and internal irrigation, used for dust suppression. Reducer working body and the motor are combined and highly integrated. Maternal body assembly line is located in the center, is a straight line and a large dump height. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage iobsluzhivanii. Standard electrical equipment higher than the national standards. The hydraulic system has a function to maintain a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection.

The compact size and user-friendly control unit creates a significant safety at work. The processor used in several new patent technology. The machine is widely used as, in deep mines at large angles of incidence of soft coal seams, in the sinking of mixed faces and in tunneling for railways, highways and reservoirs. Most Removable cross-sectional area from one position - 25.4 m², a longitudinal tilt angle ± 18º. The optimum height for the job - 2,5-4.0 m.

Roadheader EBZ-220 is a crawler designed for use in medium and heavy-duty, having the executive body of the election type. Harvester is used for sinking mines and tunnels. Combine a electrohydraulic drive system and a modular design for easy transportation, installation / removal and maintenance. Mountain mass bounces rotating cutting body is located on the harvester boom. Cutting body driven by a motor with water cooling via a two-speed epicyclic gearboxes and. Manipulation of the boom is done vertically / horizontally and with the help of hydraulic cylinders arc and moves freely in allowing selectively run in the bottom of any production profile.

Dust suppression system is located on the boom and a set of nozzles irrigate the treated area under irrigation and clove through the nozzles on the executive board. If necessary, combine harvester can be fitted with high-pressure irrigation system. Standard executive body of the axial type motor has a capacity of 220/132 kW. Repulsed rock mass is going on the feeder as it moves to the bottom of the combine. The feeder can be raised and lowered as necessary to ensure proper clearance at the stretch of the combine or work rebellion / fall produce. The feeder is equipped with a shovel stars that move the rock mass to the scraper conveyor, mounted in the center of the combine. Stars are hydraulically driven via gears mounted under the feeder.

The scraper conveyor drive is equipped with two hydraulic motors on the collapse of the conveyor and docked with the feeder is mounted on the front and rear hinge arms combine. This arrangement allows the conveyor to move with the feeder when lowering / lifting of the latter. The scraper conveyor transports the material is chipped into the tail of the car, where the shipment takes place in the mine transport systems. The movement of the combine by means of trucks. Truckee driven by a hydraulic motor through a gearbox. Each motor has a built-in trucking braking system, which is triggered when disconnecting the electrical or hydraulic systems. The brake system is also activated if the control lever Tracians in neutral. Truckee have a low ground pressure, allowing you to work in a very soft soil.

Behind the machines are auxiliary jacks for lifting the combine. These jacks are used to stabilize the harvester at work as well as the passage of the inclined workings. In addition, jacks may be used in servicing processor. The hydraulic system is equipped with oil station, consisting of a piston pump, resulting in the operation of the motor with air cooling. The hydraulic system consists of a number of high-pressure circuits and control circuits and control. All hose connections and fittings are equipped with the BRC, which makes all the hydraulic circuits are easy to service.

Cooling hydraulic and engine cutting unit is carried out using the water system of the machine. Water system directs the flow of coolant through the cooling oil tank and through the engine water jacket cutter body. Once the water has passed through all the single phase cooling system, it may be applied to the dust suppression system or removed through the drain line. Water system of the machine is equipped with pressure sensors and flow of water.

Technical specification

The sensors are connected to an electrical control circuit, which allows the engine to run the executive body only if the required level of flow / pressure water, providing cooling and irrigation.

Technical specification

Roadheader EBZ-220 for use in medium and heavy-duty, in general, is described in the technical specifications and of collected of the following:

EXECUTIVE BODY:

- Electoral executive body with one cutting unit and irrigation by clove.

Loading systems and conveyors:

- Hydraulic shovel asterisk.

- The hydraulically adjustable feeder.

- Conveyor with hydraulic drive, double-row round-link chain.

TRACKS:

- The hydraulic drive system of trucking.

- The safety brake.

- Automatic hydraulic track chain tension.

Hydraulic equipment:

- Powerpack

- БРС

- Automatic and manual pumping oil in the oil tank

COOLING SYSTEM:

- Open cooling.

ELECTRIC EQUIPMENT:

- The electrical contactor control station ..

- Engine oil station.

- The engine of the cutting body.

- Two headlights.

- Two taillights.

- Prelaunch notification.

- Emergency button to stop the machine.

- Pressure and flow rate.

JACKS:

- 2 of the support jack.

EQUIPMENT FOR GREASE:

- Individual grease through grease fittings.

| Machine Parameters | |

| Machine Length | 10400 mm |

| Machine Height | 1720 mm |

| Machine Width | 3200 mm |

| Total Weight (without Reversed Loader) | 63,5 t |

| Ground Clearance | 190 mm |

| Max. Non-removable Part Dimensions | 1х1,4 х1,4 m |

| Cutting Parameters | |

| Max. Cutting Height | 4500 mm |

| Max. Cutting Width | 5600 mm |

| Max. Dinting Depth | 180 mm |

| Cutting Motor Power | 220/132 кW |

| Rotating Speed of Cutting Head | 23 и 46 r/min |

| Economic Cutting Hardness | ≤ 85 МPа |

| Scraper Conveyor | |

| Conveyor Type | Fixed Double Circuit |

| Link Specifications | 18х64 |

| Rated Chain Speed of Scraper | 55 m/min |

| Conveyor Driver | Hydraulic |

| Loading and Conveying System | |

| Loading Mode | Chain Wheel |

| Driving Mode of the Star Wheel of Shovel Board | Hydraulic |

| Loading Chain Wheel Type | Four-axis |

| Gear Rotating Speed | 33 r/min |

| Conveying Capacity | 4 m³/min |

| TRACKS | |

| Travelling Speed | 0 - 6,0 m/min |

| Motor Mode | Hydraulic |

| Track Height | 420 mm |

| Ground Specific Pressure | 0,16МPа |

| Gradeability | ±18° |

| Oil Station | |

| Motor of Oil Station | 90 кW |

| System Pressure | 18 МPа |

| Oil Tank Capacity | 600 l |

| Water Consumption | |

| Dust Suppression | Interal & External Spraying |

| Spray Water Pressure | 3 МPа |

| Electrical Equippment | |

| Supply Voltage | 1140В 50 Hz |

| Oil Pump Motor Power | 90 кW |

| Cutting Motor Power | 220/132 кW |

| Total Power | 310/222 кW |

Description

Roadheader EBZ-220H widely used for coal mining rock tunneling and in mines, rock hardness which is not more than 9. Harvester can realize the inconvenience of cutting, loading and transportation. Layout combine a compact, low center of gravity, easy to manage, it works perfectly, destroying hard rocks. Combine meet international standards of quality and safety. Equipped with a spray and cleaning system both inside and outside. The compact arrangement of the gearbox and the engine. Reducer working body and the motor are combined and highly integrated. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage and maintain. Standard electrical equipment higher than the national standards. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection. Compact size and easy control unit creates a significant safety at work. The processor used in several new patent technology. The machine is widely used in deep mines at large angles of incidence of soft coal seams, in the sinking of mixed faces and in tunneling for railways, highways and reservoirs. Removable largest cross-sectional area from one position - 27.5 m², a longitudinal tilt angle ± 18º. The optimum height for the job - 2,5-4.0 m.

Roadheader EBZ-220H widely used for coal mining rock tunneling and in mines, rock hardness which is not more than 9. Harvester can realize the inconvenience of cutting, loading and transportation. Layout combine a compact, low center of gravity, easy to manage, it works perfectly, destroying hard rocks. Combine meet international standards of quality and safety. Equipped with a spray and cleaning system both inside and outside. The compact arrangement of the gearbox and the engine. Reducer working body and the motor are combined and highly integrated. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage and maintain. Standard electrical equipment higher than the national standards. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection. Compact size and easy control unit creates a significant safety at work. The processor used in several new patent technology. The machine is widely used in deep mines at large angles of incidence of soft coal seams, in the sinking of mixed faces and in tunneling for railways, highways and reservoirs. Removable largest cross-sectional area from one position - 27.5 m², a longitudinal tilt angle ± 18º. The optimum height for the job - 2,5-4.0 m.

Technical specification

| Machine Parameters | |

| Machine Length | 10700 mm |

| Machine Height | 1820 mm |

| Machine Width | 3300 mm |

| Total Weight (without Reversed Loader) | 72 t |

| Ground Clearance | 190 mm |

| Max. Non-removable Part Dimensions | 3.33mх1,36m х1,46m |

| Cutting Parameters | |

| Max. Cutting Height | 4500 mm |

| Max. Cutting Width | 5600 mm |

| Max. Dinting Depth | 180 mm |

| Cutting Motor Power | 220 кW |

| Rotating Speed of Cutting Head | 23 и 46 r/min |

| Economic Cutting Hardness | ≤ 90 МPа |

| Scraper Conveyor | |

| Conveyor Type | Fixed Double Circuit |

| Link Specifications | 18х64 |

| Rated Chain Speed of Scraper | 43 m/min |

| Conveyor Driver | Hydraulic |

| Loading and Conveying System | |

| Loading Mode | Chain Wheel |

| Driving Mode of the Star Wheel of Shovel Board | Hydraulic |

| Loading Chain Wheel Type | Four-axis |

| Gear Rotating Speed | 33 r/min |

| Conveying Capacity | 4,5 m³/min |

| TRACKS | |

| Travelling Speed | 0 - 5,3 m/min |

| Motor Mode | Hydraulic |

| Track Height | 450 mm |

| Ground Specific Pressure | 0,16МPа |

| Gradeability | ±18° |

| Oil Station | |

| Motor of Oil Station | 90 кW |

| System Pressure | 22 МPа |

| Oil Tank Capacity | 700 l |

| Hydraulic Pump | A11VO145/145 |

| Water Consumption | |

| Dust Suppression | Internal & External Spraying |

| Spray Water Pressure | 3 МPа |

| Electrical Equippment | |

| Supply Voltage | 1140В 50 Hz |

| Oil Pump Motor Power | 90 кW |

| Cutting Motor Power | 220 кW |

Description

Roadheader EBZ-260 widely used for coal mining rock tunneling and in mines, rock hardness which is not more than 9. Harvester can realize the inconvenience of cutting, loading and transportation. Layout combine a compact, low center of gravity, easy to manage, it works perfectly, destroying hard rocks. Combine meet international standards of quality and safety. Equipped with a spray and cleaning system both inside and outside. The compact arrangement of the gearbox and the engine. Reducer working body and the motor are combined and highly integrated. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage and maintain. Standard electrical equipment higher than the national standards. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection. Compact size and easy control unit creates a significant safety at work. The processor used in several new patent technology. The machine is widely used in deep mines at large angles of incidence of soft coal seams, in the sinking of mixed faces and in tunneling for railways, highways and reservoirs. Removable largest cross-sectional area from one position - 29.1 m², a longitudinal tilt angle ± 16º. The optimum height for the job - 2,7-4.5 m.

Roadheader EBZ-260 widely used for coal mining rock tunneling and in mines, rock hardness which is not more than 9. Harvester can realize the inconvenience of cutting, loading and transportation. Layout combine a compact, low center of gravity, easy to manage, it works perfectly, destroying hard rocks. Combine meet international standards of quality and safety. Equipped with a spray and cleaning system both inside and outside. The compact arrangement of the gearbox and the engine. Reducer working body and the motor are combined and highly integrated. The machine has an LCD display with a demonstration of the functions in dynamic, easy to manage and maintain. Standard electrical equipment higher than the national standards. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system. The contour lines of the pressure in the cutting and loading circuit is sensitive overload protection. Compact size and easy control unit creates a significant safety at work. The processor used in several new patent technology. The machine is widely used in deep mines at large angles of incidence of soft coal seams, in the sinking of mixed faces and in tunneling for railways, highways and reservoirs. Removable largest cross-sectional area from one position - 29.1 m², a longitudinal tilt angle ± 16º. The optimum height for the job - 2,7-4.5 m.

Main parameters

| Main parameters | |

| Dimensions (m) | 10.77×3.2×1.83 |

| Weight (t) | 78 |

| Locating Cutting Section Size (W×H) (m) | 5,0 х 5,8 |

| Dinting Depth (mm) | 270 |

| Ground Clearance (mm) | 210 |

| Gradeability | ±16° |

| Economic Cutting Hardness (MPa) | ≤ 90 |

| Ground Specific Pressure (MPa) | 0,17 |

| Rotating Speed of Cutting Head (r/min) | 46 |

| Dust Suppression: | Internal & External Spraying |

| Working Pressure of Internal Spraying (MPa) | 3,0 |

| Cutting Head Mode: | Spherical, Conical Pick |

| Motor Power (kW) | 260 |

| Oil Pump Motor Power (kW) | 125 |

| Gear Rotating Speed (r/min) | 26 |

| Loading Chain Wheel Type: | Four-axis |

| Coneying Capacity ( m3/min) | 4,5 |

| Rated Chain Speed of Scraper (m/min) | 62 |

| Travelling Speed (m/min) | 0 - 5,3 |

| Braking System | Stable and Reliable |

| Driving Mode of Travelling Part: | Hydraulic |

| Oil Tank Capacity (L) | 700 |

| Voltage (V) | 1140 |

| Hydraulic System Pressure (MPa) | 22 |

| Hydraulic Pump: | A11VO145/145 |

| Max. Non-removable Part Dimensions (m) | 3,39x1,39x1,47 |

Description

Roadheader EBZ-315 It is widely used for rock excavation, tunneling or in the coal mines when the fortress of rocks does not exceed 90 MPa working with loading on loaders, scrapers, self-propelled carriages. They can operate continuously for excavation, loading and transport. These conditions are best for cutting, loading and transporting rocks. Layout combine a compact, low center of gravity, stable, it has a strong and powerful prekrasnuyuupravlyaemost cutter body. Combine meets international standards of quality and safety. It has a cleaning system of internal and external reflux. Gear units and motors are very compact chassis; central transport portion is formed in a straight line and has a long and large dump height. The machine has the function of moving the display, which indicates the system works, or in need of repair; and execution of a higher than required by the national standard. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system.

Roadheader EBZ-315 It is widely used for rock excavation, tunneling or in the coal mines when the fortress of rocks does not exceed 90 MPa working with loading on loaders, scrapers, self-propelled carriages. They can operate continuously for excavation, loading and transport. These conditions are best for cutting, loading and transporting rocks. Layout combine a compact, low center of gravity, stable, it has a strong and powerful prekrasnuyuupravlyaemost cutter body. Combine meets international standards of quality and safety. It has a cleaning system of internal and external reflux. Gear units and motors are very compact chassis; central transport portion is formed in a straight line and has a long and large dump height. The machine has the function of moving the display, which indicates the system works, or in need of repair; and execution of a higher than required by the national standard. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system.

The contour line pressure in the cutting and loading circuit is sensitive overload protection. It combines a compact control unit and very compact group of control valves. The processor uses several new patent technology. The machine is widely used for drilling in the mines at large angles of incidence in the rock faces or tunnel. Combine can be used in tunneling for railways, roads or construction of water channels. Removable largest cross-sectional area from one position - 29.1 m², a longitudinal tilt angle ± 16º. The optimum height for the job - 2,7-4.5 m.

Roadheader EBZ-315 is a crawler designed for heavy duty having an executive body of the election type. Harvester is used for sinking mines and tunnels. Combine a electrohydraulic drive system and a modular design for easy transportation, installation / removal and maintenance. Mountain mass bounces rotating cutting body is located on the harvester boom. Cutting body driven by a motor with water cooling via a two-speed epicyclic gearboxes and. Manipulation of the boom is carried out by the horizontal / vertical and in an arc using the hydraulic cylinders and moves freely in the work, allowing selectively run in the bottom of any production profile.

Dust suppression system is located on the boom and a set of nozzles irrigate the treated area under irrigation and clove through the nozzles on the executive board. If necessary harvester can be equipped with a high pressure irrigation. Standard executive body of the axial type motor has a capacity of 315 kW. Repulsed rock mass is going on the feeder as it moves to the bottom of the combine. The feeder can be raised and lowered as necessary to ensure proper clearance at the stretch of the combine or work rebellion / fall produce. The feeder is equipped with a shovel stars that move the rock mass to the scraper conveyor, mounted in the center of the combine. Stars are hydraulically driven via gears mounted under the feeder.

The scraper conveyor is equipped with hydraulic motors drive two to reset the conveyor and docked with the feeder is mounted on the front and rear hinge arms combine. This arrangement allows the conveyor to move with the feeder when lowering / lifting of the latter. The scraper conveyor transports the material is chipped into the tail of the car, where the shipment takes place in the mine transport systems. The movement of the combine by means of trucks. Truckee driven by hydraulic motors through gears. Each motor has a built-in trucking braking system, which is triggered when disconnecting the electrical or hydraulic systems. The brake system is also activated if the control lever Tracians in neutral. Truckee have a low ground pressure, allowing you to work in a very soft soil.

Behind the machines are auxiliary jacks for lifting the combine. These jacks are used to stabilize the harvester at work as well as the passage of the inclined workings. In addition, jacks may be used in servicing processor. The hydraulic system is equipped with oil station, consisting of a piston pump, resulting in the operation of the motor with air cooling. The hydraulic system consists of a number of high-pressure circuits and control circuits and control. All hose connections and fittings are equipped with the BRC, which makes all the hydraulic circuit to maintain comfortable.

Cooling system and hydraulic motor of the cutting body is carried out by means of the water system of the machine. Water system directs the flow of coolant through the cooling oil tank and through the water jacket of the engine of the cutting body. Once the water has passed through all the single phase cooling system, it may be applied to the dust suppression system, or disposed of through the drain line. Water system of the machine is equipped with pressure sensors and flow of water. The sensors are connected to the electrical control circuit that allows you to start the engine of the executive body only if the required level of flow / pressure water, providing cooling and irrigation.

Main parameters

| Parameters | |

| Dimensions (m) | 10.74×3.3×1.83 |

| Weight (t) | 86 |

| Locating Cutting Section Size (W×H) (m) | 5,0 х 5,85 |

| Dinting Depth (mm) | 190 |

| Ground Clearance (mm) | 190 |

| Track Height (mm) | 822 |

| Gradeability | ±16° |

| Economic Cutting Hardness (MPa) | ≤ 90 |

| Ground Specific Pressure (MPa) | 0,17 |

| Rotating Speed of Cutting Head (r/min) | 46 |

| Dust Suppression: | Internal & External Spraying |

| Working Pressure of Internal Spraying (MPa) | 3,0 |

| Cutting Head Mode: | Spherical, Conical Pick |

| Motor Power (kW) | 315 |

| Oil Pump Motor Power (kW) | 132 |

| Gear Rotating Speed (r/min) | 28 |

| Loading Chain Wheel Type: | Four-axis |

| Coneying Capacity ( m3/min) | 4,5 |

| Rated Chain Speed of Scraper | 43 |

| Travelling Speed (m/min) | 0 - 5,0 |

| Braking System | отказоустойчивая |

| Driving Mode of Travelling Part: | Hydraulic |

| Oil Tank Capacity (L) | 850 |

| Voltage (V) | 1140 |

| Hydraulic System Pressure (MPa) | 18 |

| Hydraulic Pump: | Double-piston |

| Max. Non-removable Part Dimensions (m) | 3,4x1,4x1,48 |

Parameters

|

Dimensions |

LWL-60/30L |

|

|

Track Length |

1850 mm |

|

|

Inner Width of Track |

900 mm (AC) |

|

|

Link Width of Track |

300/400 mm |

|

|

Ground Clearance |

320 mm (AC) |

|

|

Inner Width of Conveying Chute |

488 mm |

|

|

Transportation Condition

|

Length |

6750 mm |

|

Width |

1490 mm |

|

|

Height |

1650 mm |

|

|

Working Condition

|

Length |

7300 mm |

|

Width |

1490 mm |

|

|

Height |

1750 mm |

|

|

Scope of Work |

||

|

A |

Excavating Width |

3070 mm |

|

B |

Excavating Length (groove) |

1530 mm |

|

C |

Excavating Height |

2300 mm |

|

D |

Excavating Depth |

500 mm |

|

E |

Dumping Height |

1400 mm (variable) |

|

F |

Min. Loading Height |

1350 mm (variable) |

|

G |

Dumping Distance |

1600 mm (variable) |

|

H |

Max. Rotary Angle of Working Arm |

±35° |

|

|

Applied Roadway Section (W×H) |

≥2×2 m |

Characteristics

|

Performance and Paramenters |

|

|

Loading Capacity |

60 m3/h |

|

Total Power of Motor |

30 kw |

|

Weight |

7200 kg |

|

Travelling Speed |

0.2±5% m/s |

|

Type of Scraper Conveyor |

Single Chain, Single Drive |

|

Applied Roadway Gradient |

≤32° |

|

Min. Turning Radius |

≥4m |

|

Ground Specific Pressure |

≤0.1 Mpa |

|

Mode of Operation |

Hydraulic Control |

|

Chain Speed of Scraper Chain |

25m/min |

|

Capacity of Hydraulic Oil Tank |

135 L |

|

Max. Working Pressure |

22 Mpa |

|

Hydraulic Pump |

gear pump×4 |

|

Hydraulic Travel Motor |

Hydraulic Motor with 2 Radial Cylinders |

|

Hydraulic Motor Chassis |

Hydraulic Motor with 1 Radial Cylinder |

Technical Parameters

| Technical Parameters | |

| Loading Capacity (m3/h) | 60 |

| Min. Turning Radius (m) | ≤4 |

| Ground Clearance (mm) | ≥280 |

| Excavating Width (mm) | 4274 |

| Loading Width (mm) | 4274 |

| Excavating Height (mm) | 2300 |

| Working Height (mm) | 1770 |

| Dumping Height (mm) | 1350 |

| Dinting Depth (mm) | 500 |

| Max. Gradeability | 15 |

| Chain Speed (m/min) | 25 |

| Total Power (kW) | 30 |

| Travelling Speed (m/sec) | 0,2 |

| Rated Working Pressure (MPa) | 20 |

| Opening Pressure of Safety Valve (MPa) | 22 |

| Working Temperature | -5 to +40 |

| Weight (kg) | 7200 |

| Oil Tank Capacity (L) | 135 |

| Dimensions (L×W×H) (mm) | 6750*1490*1650 |

| Dimensions in Working Condition (L×W×H) (mm) | 7300*1490*1750 |

| Cooling Method | Air |

| Control Type | Hydraulic |

| Dimensions in Transportation Condition (m) | 3200*1490*900 |

| Max. Swing Angel of Working Arm (left-right) | -90 to +90 |