Description

Roadheader EBZ-315 It is widely used for rock excavation, tunneling or in the coal mines when the fortress of rocks does not exceed 90 MPa working with loading on loaders, scrapers, self-propelled carriages. They can operate continuously for excavation, loading and transport. These conditions are best for cutting, loading and transporting rocks. Layout combine a compact, low center of gravity, stable, it has a strong and powerful prekrasnuyuupravlyaemost cutter body. Combine meets international standards of quality and safety. It has a cleaning system of internal and external reflux. Gear units and motors are very compact chassis; central transport portion is formed in a straight line and has a long and large dump height. The machine has the function of moving the display, which indicates the system works, or in need of repair; and execution of a higher than required by the national standard. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system.

Roadheader EBZ-315 It is widely used for rock excavation, tunneling or in the coal mines when the fortress of rocks does not exceed 90 MPa working with loading on loaders, scrapers, self-propelled carriages. They can operate continuously for excavation, loading and transport. These conditions are best for cutting, loading and transporting rocks. Layout combine a compact, low center of gravity, stable, it has a strong and powerful prekrasnuyuupravlyaemost cutter body. Combine meets international standards of quality and safety. It has a cleaning system of internal and external reflux. Gear units and motors are very compact chassis; central transport portion is formed in a straight line and has a long and large dump height. The machine has the function of moving the display, which indicates the system works, or in need of repair; and execution of a higher than required by the national standard. The hydraulic system has a function of maintaining a constant pressure in the hydraulic system.

The contour line pressure in the cutting and loading circuit is sensitive overload protection. It combines a compact control unit and very compact group of control valves. The processor uses several new patent technology. The machine is widely used for drilling in the mines at large angles of incidence in the rock faces or tunnel. Combine can be used in tunneling for railways, roads or construction of water channels. Removable largest cross-sectional area from one position - 29.1 m², a longitudinal tilt angle ± 16º. The optimum height for the job - 2,7-4.5 m.

Roadheader EBZ-315 is a crawler designed for heavy duty having an executive body of the election type. Harvester is used for sinking mines and tunnels. Combine a electrohydraulic drive system and a modular design for easy transportation, installation / removal and maintenance. Mountain mass bounces rotating cutting body is located on the harvester boom. Cutting body driven by a motor with water cooling via a two-speed epicyclic gearboxes and. Manipulation of the boom is carried out by the horizontal / vertical and in an arc using the hydraulic cylinders and moves freely in the work, allowing selectively run in the bottom of any production profile.

Dust suppression system is located on the boom and a set of nozzles irrigate the treated area under irrigation and clove through the nozzles on the executive board. If necessary harvester can be equipped with a high pressure irrigation. Standard executive body of the axial type motor has a capacity of 315 kW. Repulsed rock mass is going on the feeder as it moves to the bottom of the combine. The feeder can be raised and lowered as necessary to ensure proper clearance at the stretch of the combine or work rebellion / fall produce. The feeder is equipped with a shovel stars that move the rock mass to the scraper conveyor, mounted in the center of the combine. Stars are hydraulically driven via gears mounted under the feeder.

The scraper conveyor is equipped with hydraulic motors drive two to reset the conveyor and docked with the feeder is mounted on the front and rear hinge arms combine. This arrangement allows the conveyor to move with the feeder when lowering / lifting of the latter. The scraper conveyor transports the material is chipped into the tail of the car, where the shipment takes place in the mine transport systems. The movement of the combine by means of trucks. Truckee driven by hydraulic motors through gears. Each motor has a built-in trucking braking system, which is triggered when disconnecting the electrical or hydraulic systems. The brake system is also activated if the control lever Tracians in neutral. Truckee have a low ground pressure, allowing you to work in a very soft soil.

Behind the machines are auxiliary jacks for lifting the combine. These jacks are used to stabilize the harvester at work as well as the passage of the inclined workings. In addition, jacks may be used in servicing processor. The hydraulic system is equipped with oil station, consisting of a piston pump, resulting in the operation of the motor with air cooling. The hydraulic system consists of a number of high-pressure circuits and control circuits and control. All hose connections and fittings are equipped with the BRC, which makes all the hydraulic circuit to maintain comfortable.

Cooling system and hydraulic motor of the cutting body is carried out by means of the water system of the machine. Water system directs the flow of coolant through the cooling oil tank and through the water jacket of the engine of the cutting body. Once the water has passed through all the single phase cooling system, it may be applied to the dust suppression system, or disposed of through the drain line. Water system of the machine is equipped with pressure sensors and flow of water. The sensors are connected to the electrical control circuit that allows you to start the engine of the executive body only if the required level of flow / pressure water, providing cooling and irrigation.

Main parameters

| Parameters |

| Dimensions (m) |

10.74×3.3×1.83 |

| Weight (t) |

86 |

| Locating Cutting Section Size (W×H) (m) |

5,0 х 5,85 |

| Dinting Depth (mm) |

190 |

| Ground Clearance (mm) |

190 |

| Track Height (mm) |

822 |

| Gradeability |

±16° |

| Economic Cutting Hardness (MPa) |

≤ 90 |

| Ground Specific Pressure (MPa) |

0,17 |

| Rotating Speed of Cutting Head (r/min) |

46 |

| Dust Suppression: |

Internal & External Spraying |

| Working Pressure of Internal Spraying (MPa) |

3,0 |

| Cutting Head Mode: |

Spherical, Conical Pick |

| Motor Power (kW) |

315 |

| Oil Pump Motor Power (kW) |

132 |

| Gear Rotating Speed (r/min) |

28 |

| Loading Chain Wheel Type: |

Four-axis |

| Coneying Capacity ( m3/min) |

4,5 |

| Rated Chain Speed of Scraper |

43 |

| Travelling Speed (m/min) |

0 - 5,0 |

| Braking System |

отказоустойчивая |

| Driving Mode of Travelling Part: |

Hydraulic |

| Oil Tank Capacity (L) |

850 |

| Voltage (V) |

1140 |

| Hydraulic System Pressure (MPa) |

18 |

| Hydraulic Pump: |

Double-piston |

| Max. Non-removable Part Dimensions (m) |

3,4x1,4x1,48 |

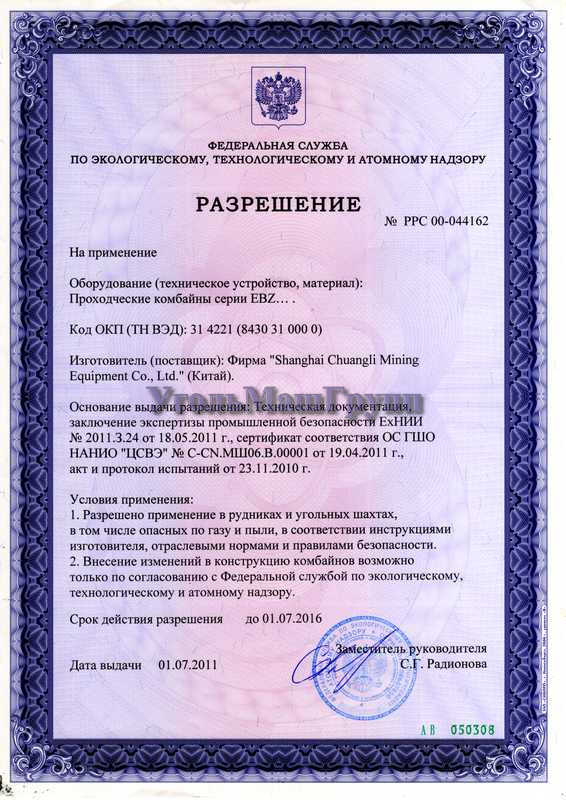

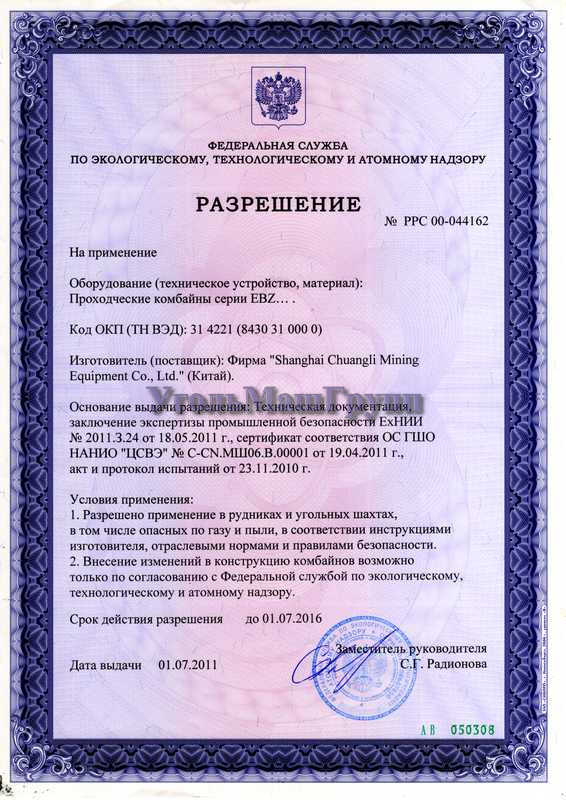

Sertificate